Right Here Is A Closer Take A Look At What Is Powder Coating?

Usually, the term powder Coating describes a type of Coating that is used as free-flowing dry powder, then treated with heat or ultraviolet light. This type of Coating is different from standard fluid paint, which is provided using vaporizing solvents.

Prep work of powder Coating parts

Getting your powder coated parts prepared is a procedure. It entails a series of steps that can range from simple to specify. If you wish to make sure that your ended up item is excellent, you need to make sure to comply with the appropriate actions.

The very first step is to remove any dirt, dirt as well as other surface area contaminations. You can utilize a stress washing machine or simply saturate the parts in tidy water.

The following action is to sandblast the surface to eliminate any type of defects as well as provide structure. This is likewise essential to ensure that the powder coat sticks correctly. Sandblasting can be done with a variety of unpleasant media. Picking a tidy sandblasting media is necessary to ensure a successful powder layer.

The powder layer procedure includes the application of a polymer combined with pigments. This is then cured in a treating stove. The procedure is relatively easy as well as economical. Depending upon the part dimension, the healing time will certainly vary. The temperature level ought to be set according to the supplier's requirements.

One of the most important step is the pre-treatment. This is the very best way to guarantee that your powder coat is used appropriately. It includes removing oil from steel pores, getting rid of any kind of paint that may be remaining externally, and also cleaning the surface area of dirt and also crud.

Eco-friendly alternative to solvent-laden paints

Using an eco-friendly option to solvent-laden paints is currently a practical alternative. For a little investment, you can change poisonous paints with eco-friendly ones that are without harmful chemicals.

These paints are not just much healthier for the setting, yet they can additionally save you cash in the future. They can conserve you five to $11 per vehicle. They also aid you reduce discharges, which indicates much less co2 airborne.

One of the best environmentally friendly alternatives to solvent-laden paints is latex paint. They have a lower VOC material as well as do not emit a scent like other paints. They can also be a good option for LEED debts.

powder coat los angeles is one that makes use of steels as pigments. Paints that utilize metals in the pigment can be more secure than chemical pigments.

Numerous firms have actually collaborated to make items that are both reduced in VOCs and high in safety. Among these companies is ECOS Paints. They market a range of paints, varnishes, and also discolorations. They are made from all-natural components and are devoid of toxic chemicals. They are packaged with biodegradable product packaging and also 100% recycled plastic.

They are additionally accredited by the Eco-friendly Seal program, which restricts the dangerous chemicals in their products. An additional option is Colorhouse. They have a lovely selection of colors and also emphasize sustainability and recycling. They also make use of metals and also unsafe ingredients as minimally as possible. They are also LEED Compliant and also MPI Extreme Environment-friendly accredited.

Can be recovered and reused

Using powder finishes can lower the ecological influences of using solvents. Powder Coating systems additionally minimize expenses connected to the risk-free disposal of unstable natural substances. Powder coverings are utilized in lots of markets. They are durable as well as immune to corrosion and also fading. They are also offered in a wide variety of colors, gloss levels, as well as appearances.

The powder Coating procedure permits parts to be delivered immediately after curing. This minimizes the quantity of time that parts spend in inventory. It additionally assists to decrease waste.

One of the most efficient way to reuse powder overspray is by recouping it. Recovery systems can recover as much as 98 percent of the overspray. This is a terrific way to decrease waste and also conserve money.

A powder recuperation system is included a recovery cubicle, a collection agency, and also filters. The collector will accumulate overspray from the recuperation cubicle. It will certainly after that be carried to a feed hopper. Some feed hoppers will shake to aid protect against powder clumping.

Recuperation systems will not constantly return the same ratio of base to result as virgin powder. Additionally, some powder might be lost in the collection filters. Using a cartridge-style purification system will minimize the amount of deterioration of the powder.

The recovery procedure can also increase step-by-step performance. For browse this site , it can enable parts to be piled more detailed with each other on a conveyor. This can likewise allow even more components to pass through the production line in less time.

Here Are The Benefits Of Powder Coating

Unlike fluid paint, which is delivered with vaporizing solvent, powder Coating is used as a free-flowing completely dry powder, after that treated with heat or ultraviolet light. Powder Coating is applied to surfaces in order to protect them from environmental damages as well as scrapes.

Pretreatment

Getting a superb pretreatment before powder Coating is a must to get a durable, rust resistant Coating. Along with boosting the bond of the powder to the substrate, it additionally supplies the steel with a safety layer.

The process can be a dip, spray, or a combination of several approaches. The option of process relies on the type of item being layered and also the client's requirements. The performance of the pretreatment need to be matched to the specs of the powder coat, in addition to the materials utilized in the pretreatment.

The first step in preparing a component for powder Coating is to get rid of surface soils. Some typical approaches consist of pressure washing, sandblasting, and also advanced media blasting. The quantity of dirt that needs to be eliminated will differ depending on the type of product being coated.

Electrostatic spray deposition approach

Using electrostatic spray deposition, a powder blend is sprayed onto a steel surface area. The electrostatic tourist attraction between the powder bits as well as the steel surface causes a finishing that shields the underlying material from corrosion. This Coating uses a selection of coatings as well as appearances. The Coating is additionally available in a variety of colors.

The electrostatic spray deposition process includes making use of an electrostatic spray gun and a powder spray cubicle. This system is an usual approach of using powder finishes. A corona spray gun is a common electrostatic spray gun. The electrostatic spray gun contains a nozzle that produces high voltage to create an electrostatic field in between the steel foil and also the spray blend. The powder mixture is then splashed via the nozzle to the steel surface area.

Fluidized powder coating motorcycle wheels near me

Unlike conventional fluid finishings, the Fluidized bed powder Coating technique is a lot more environmentally friendly. It is additionally a lot cheaper. It provides a tough, smooth surface area with exceptional resilience. It can be related to different objects such as metal superstructures, covering equipment, and airplane components.

Fluidized bed powder Coating method is additionally made use of on numerous parts that are subject to high temperatures. It protects the component against corrosion and ecological effects. It additionally smooths over small details. During the process, parts are preheated and after that dipped into a "fluidized bed" of plastic powder. Later, the parts are cured in a stove. This kind of Coating is excellent for parts with Faraday cage results.

Unlike fluid finishes, the Fluidized bed powder method creates heavy layers in one dip. This sort of Coating approach has high transfer performance. It likewise eliminates the requirement for overspray healing systems.

Cross-contamination

Using powder Coating to coat an item can be really efficient. However, it is very important to utilize the appropriate powder and to follow excellent contamination control techniques to make certain an excellent quality finish.

Cross-contamination takes place when a part or powder is revealed to contaminants such as dust, dirt, oil, and steel chips. The end result might be a defect in the surface, which could lead to a dissatisfied customer.

The smallest speck of dust might wreck a powder covered item. For this reason, it is necessary to guarantee that the powder and also the air in the powder Coating area are clean. powder coating motorcycle wheels santa clarita is also crucial to guarantee that the room is well filteringed system. This will make sure that the dirt from the rest of the building is not able to penetrate the powder Coating room.

Toughness

Among the many benefits of powder Coating is its sturdiness. It is made use of on a variety of items. It provides resistance to impact, abrasion, deterioration, and chemicals. It can last for years, also decades, if it is used appropriately.

Powder Coating is likewise less destructive to the atmosphere than standard liquid paint completing. It launches minimal amounts of unpredictable organic compounds (VOCs) right into the ambience. It is also very easy to tidy. It is quickly cleaned with warm water.

Powder Coating provides a wide variety of structures, from smooth surfaces to harsh structures. It is also offered in a range of surfaces, from shiny to matte.

Powder Coating can endure smog, UV radiation, and also acidic problems. It is likewise very immune to corrosion, breaking, and weather. https://zenwriting.net/valentine765perry/this-post-intends-to-supply-an-intro-to-this-important-subject-regarding can be put on many different sorts of materials, such as steel, plastic, and glass. It is extensively used in many sectors, including building, farming, electrical design, as well as the production of mechanical parts.

Right Here Is A Closer Take A Look At What Is Powder Coating?

Generally, the term powder Coating refers to a type of Coating that is used as free-flowing dry powder, after that treated with warm or ultraviolet light. This sort of Coating is various from traditional liquid paint, which is delivered by means of vaporizing solvents.

Prep work of powder Coating parts

Getting your powder covered parts ready is a process. It involves a collection of actions that can range from easy to specify. If you wish to ensure that your completed product is excellent, you have to be sure to comply with the best actions.

The first step is to remove any type of dirt, dust and various other surface impurities. You can use a stress washer or merely soak the parts in tidy water.

The next step is to sandblast the surface to eliminate any type of imperfections as well as provide appearance. This is likewise crucial to make certain that the powder layer adheres properly. Sandblasting can be done with a selection of rough media. Picking a clean sandblasting media is essential to guarantee an effective powder coat.

The powder layer process includes the application of a polymer combined with pigments. This is after that cured in a treating stove. The procedure is reasonably straightforward and also low-cost. Depending on the part size, the healing time will certainly differ. The temperature level needs to be set according to the producer's requirements.

One of the most essential action is the pre-treatment. This is the best means to guarantee that your powder layer is applied effectively. It involves getting rid of oil from metal pores, getting rid of any kind of paint that might be sticking around externally, and cleaning the surface area of dust and gunk.

Eco-friendly option to solvent-laden paints

Making use of an eco-friendly option to solvent-laden paints is currently a practical choice. For a small investment, you can replace hazardous paints with green ones that are devoid of unsafe chemicals.

These paints are not only healthier for the environment, yet they can likewise conserve you money in the long run. They can save you 5 to $11 per vehicle. They additionally assist you lower discharges, which suggests less carbon dioxide airborne.

One of the best environmentally friendly alternatives to solvent-laden paints is latex paint. https://lauren523cameron.wordpress.com/2022/11/28/this-post-intends-to-supply-an-introduction-to-this-essential-topic-concerning-powder-coating/ have a reduced VOC content and do not discharge an odor like various other paints. They can additionally be an excellent option for LEED credits.

https://www.powderbulksolids.com/mixers-blenders/coperion-extruders-expand-kansai-helios-powder-coating-production -friendly paint is one that uses steels as pigments. Paints that use steels in the pigment can be safer than chemical pigments.

A number of firms have collaborated to make items that are both low in VOCs and also high in safety. One of these companies is ECOS Paints. They sell a variety of paints, varnishes, and stains. They are made from all-natural ingredients and also are without harmful chemicals. They are packaged with biodegradable product packaging and 100% recycled plastic.

They are also licensed by the Eco-friendly Seal program, which limits the dangerous chemicals in their products. Another option is Colorhouse. They have a gorgeous option of shades as well as stress sustainability and also recycling. They likewise utilize metals and unsafe components as minimally as possible. They are also LEED Compliant as well as MPI Extreme Eco-friendly certified.

Can be recouped as well as recycled

Making use of powder layers can lower the ecological impacts of using solvents. Powder Coating systems likewise minimize prices associated with the risk-free disposal of unpredictable organic compounds. Powder coatings are utilized in many markets. They are durable and also immune to deterioration and also fading. They are also readily available in a wide range of colors, gloss degrees, as well as textures.

The powder Coating process enables parts to be shipped promptly after curing. This lowers the quantity of time that parts invest in supply. It additionally helps to decrease waste.

One of the most effective means to recycle powder overspray is by recovering it. Recovery systems can redeem approximately 98 percent of the overspray. This is a great way to minimize waste and conserve money.

A powder recovery system is included a recuperation booth, a collection agency, and filters. The enthusiast will accumulate overspray from the recovery booth. It will certainly then be carried to a feed hopper. Some feed hoppers will certainly shake to help protect against powder clumping.

Recovery systems will certainly not always return the same ratio of base to effect as virgin powder. In addition, some powder may be lost in the collection filters. Utilizing a cartridge-style filtering system will certainly reduce the quantity of degradation of the powder.

The recuperation procedure can likewise increase step-by-step efficiency. For example, it can allow parts to be stacked closer with each other on a conveyor. This can also enable more parts to go through the assembly line in less time.

Powder Coating - Shield Your Metal Items From Rust

Whether you desire a coat of paint or you want to make a new look for your office or home, there are various kinds of finishings offered. Powder Coating is one kind of Coating that you may want to take into consideration. Unlike traditional fluid paint, powder Coating can be applied as a free-flowing completely dry powder as well as healed with heat or ultraviolet light.

Electrostatic spray deposition approach

Utilizing electrostatic spray deposition to use a powder Coating to a non-metallic part can be a reliable means to shield the underlying material from deterioration. Using powder coating in los angeles will enable an also application as well as a smooth coating.

The powder Coating process includes a chain reaction which creates lengthy molecular chains. https://joaquin763shirlee.wordpress.com/2022/11/28/this-post-goes-over-the-benefits-of-powder-coating/ are very sturdy as well as withstand malfunction. The chain reaction additionally produces a smooth finish.

There are two typical methods to use powder Coating. Firstly, using an electrostatic spray gun. This technique is commonly referred to as dipping.

The various other method is utilizing a fluidised bed. Using this method entails dipping the component right into a fluidized powder. The powder is then splashed making use of a high-powered electrostatic spray gun.

Both techniques are fairly affordable and also offer an also, difficult surface. They are additionally much more resilient than fluid applications. This is because the spray gun makes use of high-voltage to force the powder into the part.

Fluidized bed powder Coating method

Essentially, the fluidized bed powder Coating method is a procedure in which a part is preheated and after that dipped into a fluidized bed of put on hold powder. The powder sticks to the component by electrostatic pressures. This process is typically used for coatings with high leaks in the structure products.

Typical application methods include the completely dry powder Coating approach and electrostatic spray deposition. These methods provide numerous advantages over fluid coatings. They are economical as well as produce a thicker Coating. The thickness of the Coating is dependent on the powder chemistry as well as the dwell time.

The powder Coating procedure uses finely ground pigment or polymeric material to use a layer. It additionally utilizes a recovered powder to enhance powder Coating transfer efficiency. It can be applied to a large range of items.

It can be utilized for Coating metal superstructures. It likewise functions well for Coating small products. It is additionally valuable for Coating parts that are susceptible to corrosion.

Concealing products are used

Numerous masking items are utilized in the powder Coating procedure. These products are created to protect parts from the application procedure. Furthermore, these items can be made use of to mask areas that are not called for to receive powder Coating. These areas can be mating surfaces or electric conductivity.

The most usual masking product used is heat polyester tape. These tapes are designed to be made use of in the powder Coating process as well as are resistant to extreme treatment temperatures. These tapes are offered in a selection of sizes and shapes. They can be acquired on a roll or pre-cut.

One more usual powder Coating concealing item is silicone. This kind of concealing material is resistant to high temperatures and also can be utilized in applications that require hostile chemicals. Additionally, it has a glue that is immune to heats as well as can be easily gotten rid of after high warm procedures.

Various other masking items consist of cork and also paper. Cork can be used in low temperature finishing processes. Nevertheless, these materials are not as flexible as silicone or neoprene tapered plugs.

Resilience

Making use of powder Coating on your steel things allows them to be resistant to rust, weather condition, and also chemicals. It also helps them last longer. Typically, these coverings will certainly last approximately two decades.

The toughness of powder Coating is figured out by the type of product utilized and the application technique. On top of that, the quality of the coating is likewise an aspect. It is essential to guarantee that the materials are clean and remain in conformity with neighborhood codes.

Powder layered products are usually more immune to corrosion, chips, and also scrapes. They also withstand deterioration better than various other treatments.

Powder Coating is a cost effective alternative for numerous jobs. It is offered in a variety of colors and also textures. It is likewise eco-friendly. Compared to https://www.pfonline.com/articles/causes-and-fixes-for-liquid-paint-defects finishing, powder Coating makes use of much less hazardous waste and launches minimal VOCs into the environment.

Powder Coating is also used to layer numerous usual family objects, consisting of home appliances, home pipes, and also kitchen area surface areas. It is likewise made use of on a variety of structure jobs. It additionally supplies a resilient finish that can last as much as a decade in good conditions.

The Advantages As Well As Drawbacks Of Powder Coating

Unlike standard liquid paint, powder Coating is applied as a free-flowing, dry powder, which is after that cured with heat or ultraviolet light. Furthermore, powder Coating is typically applied electrostatically.

Electrostatic spray gun

Utilizing an Electrostatic spray gun for powder Coating is a fantastic means to produce a top quality coating on your work. Read the Full Guide is made use of to produce a durable surface that can hold up against rust and also damaging.

The electrostatic spraying method utilizes compressed air to transfer the powder to the workpiece. The gun develops a high-voltage electrostatic field that attracts the powder bits to the metal. This develops a layer that sticks to the steel in a thick, also coat.

One of the most apparent advantage of an Electrostatic spray gun is enhanced transfer effectiveness. This enables an extra uniform coat, less overspray, as well as much less waste.

There are several setups to choose from on your Electrostatic spray gun. Selecting the right ones can boost your powder Coating performance. There are a couple of essential setups to be knowledgeable about.

The kilovolt (kV) is the system of measure for the electrostatic powder gun fee. The higher the voltage, the even more dimples you will see in your Coating. It is best to establish the voltage reduced to attain the very best results.

Polymer material systems

Numerous polymer resin systems are made use of in the manufacture of powder Coating. They are developed to supply durable layers with a selection of colors and textures. They are likewise an eco-friendly option to fluid paints.

Typical powder coverings are formulated with a mix of pigments and also ingredients. These ingredients are thawed, combined, and then ground into a powder. They are after that put on the substratum utilizing electrostatic spray deposition. The powder is then cured in a healing oven.

Powder coverings are made to be hard, durable, and have exceptional adhesion. They are applied to a wide array of surfaces, consisting of plastics, metals, and tool thickness fiber board. Powder coverings are a cost-effective remedy to standard Coating techniques. They are also eco-friendly, as they make use of fewer unstable natural substances (VOCs) and also can be reused.

The major parts of thermoplastic powder finishings are a stabilizer, progressing representatives, and crosslinking resin. These ingredients should be thoroughly controlled to guarantee correct diffusion and also optimum circulation. Furthermore, relevant internet site of the Coating should be kept low to decrease movie problems.

Surfaces that can be covered

Making use of powder Coating to layer surface areas can be an economical choice to wet paint. Besides being less expensive, it can be much easier to maintain as well as clean. Additionally, it is environmentally friendly. It pushes back corrosive materials and has a wide variety of coatings.

powder coating santa clarita, los angeles county

Powder Coating can be made use of on a variety of surfaces, consisting of plastics, metal, and also glass. Its resilient finish makes it a good choice for architectural applications. However, it does have its limitations.

Some metals can not be powder covered. As an example, specific fillers can't stand up to the high temperatures of the curing process. Likewise, glass is a challenging product to powder coat.

Other than the reality that it's environmentally friendly, powder Coating is additionally an exceptional protective Coating. This coating stands up to scratches and abrasions and also gives an easy-to-clean finish.

Although it isn't the easiest to clean, powder coated products can be easily recovered with a soft brush and also a little bit of mild soap in water. Usage filtered water for best outcomes.

Drawbacks

Making use of powder Coating for completing industrial products has many benefits, however it also has its negative aspects. These consist of high startup prices, minimal shade range, as well as difficulties applying a thin coat. In spite of these disadvantages, powder coverings supply a resilient coating and also are immune to scratches.

Powder finishings are eco-friendly. They have very low emissions of unpredictable natural substances, or VOCs. They also have much less co2 emissions as well as are much more efficient in paint intake. They also eliminate the requirement for costly contamination control devices.

Powder Coating additionally has the advantage of being simpler to tidy up. Nevertheless, it is essential to maintain the spray booth area tidy between shade modifications. If the cubicle is unclean up effectively, it can lead to cross-contamination.

Powder Coating can also chip or flake off in specific conditions. This can be because of improper prep work, or even as a result of rust. Consequently, it is important to prevent storage problems that allow moisture to collect externally. Additionally, powder Coating can break down if it is subjected to UV light.

This Write-Up Aims To Provide An Introduction To This Crucial Topic About Powder Coating

Unlike liquid paint, which is delivered by means of an evaporating solvent, powder Coating is used as a dry powder as well as healed with heat or ultraviolet light. It can be used on a selection of substrates, including timber, steel, light weight aluminum, fiberglass and also plastic.

Electrostatic procedure

Created in the very early 1950s by a German scientist, electrostatic powder Coating is a completing procedure that uses an electrical charge to stick powder to metal. It can be made use of on many types of items. Electrostatic coverings have a number of benefits over liquid and also damp paint.

Electrostatic powder Coating is a long lasting finish that can be made use of on a lot of steels. This method is additionally made use of to coat electrical parts. It is a prominent approach for ending up external metal siding, grass furnishings, as well as wire shelving.

Electrostatic powder Coating utilizes an unique device to create a static area on a surface area. It then applies a completely dry powdered paint to the surface.

mouse click the following web site

Using powder Coating for your metal surface areas offers a difficult, lasting finish that is resistant to rust, deterioration, chemicals, and also effects. Powder coated steel can last as long as twenty years.

Powder Coating additionally gives a smooth finish. The bits that make up powder Coating have an electrostatic cost that draws in the steel. After the particles have actually bound to the surface area, they are baked in an oven at 400 degrees. This creates a resilient coating that will certainly not peel or chip.

Along with a long lasting surface, powder Coating is eco-friendly. Unlike standard fluid finishings, powder finishes do not contain solvents or toxins. In fact, powder coverings meet many environmental management policies.

https://www.coatingsworld.com/contents/view_online-exclusives/2022-10-26/a-guide-to-antimicrobial-coatings/ -friendliness

Picking eco-friendly products is essential to guarantee our earth stays healthy and balanced. There are a number of alternatives when it concerns paint, yet powder Coating has the least effect on the setting. It additionally gives you a surface that will last. It's easy to apply as well as is more economical than liquid paint.

Powder Coating is a procedure that utilizes finely ground fragments that are electrostatically credited develop a difficult surface. The Coating is cured in a specialized oven. It's durable and also will protect versus scratches, UV rays, and climate direct exposure.

Cost-effectiveness

Compared to liquid Coating, powder Coating is a cheaper procedure. It is also a much safer process, with fewer threats as well as much less exhausts. The advantages of powder Coating can add up to considerable cost savings gradually. Furthermore, powder Coating can increase the quality of the surface and also conserve time and money.

Among the best aspects of powder Coating is that it supplies exceptional corrosion defense. This means it is less most likely to corrode throughout setting up, product packaging and handling.

Additionally, powder Coating can be used in a variety of shades and textures. This permits greater flexibility in the finisher's application alternatives. It is likewise much less most likely to loosen from the substrate than damp paint.

Applicability to non-metallic substrates

Utilizing powder Coating on non-metallic substratums can provide a vast array of buildings, consisting of improved corrosion resistance, durability, as well as functional efficiency. These layers can be applied in a variety of appearances as well as colors, and are developed for decorative, safety, and practical applications.

Utilizing powder Coating on non-metallic surfaces calls for applying the Coating powder to the substratum in an uniform manner. If the Coating is not applied consistently, the substratum may expand or shrink, warp, or kind flaws on the completed surface area.

Non-metal substratums include ceramics, timbers in all-natural or engineered forms, as well as glass. Commonly, these surface areas are machined to develop layouts and also shapes. The substrates might additionally be transmitted. The final coating might vary from matte to shiny, relying on the application.

Pretreatment devices called for

Making use of the ideal pretreatment devices is necessary to maximizing your Coating process. The devices should be created to suit your requirements as well as performance demands. As an example, you'll need to see to it that your water high quality is of excellent quality to ensure that your powder Coating process is successful.

The initial step in preparing a surface for powder Coating is cleaning. Cleaning up gets rid of dirts as well as other surface contaminants to ensure that your powder Coating is bound correctly.

Some usual cleansers include acids and solvents. Nonetheless, you'll additionally require stronger approaches to remove pollutants that are resistant to the common cleansers.

Downsides

Contrasted to damp paints, powder Coating is much more sturdy and also supplies a resilient coating. Powder Coating is likewise very eco-friendly as it does not release unpredictable natural compounds (VOCs) into the air. These gases are damaging to the air top quality. Powder Coating is likewise much more immune to scrapes as well as breaking.

powder coating santa clarita, los angeles county

In addition to the advantages of powder Coating, there are likewise some downsides. A few of these consist of the high startup costs, high lead-time and difficulty in shade matching. Nevertheless, powder Coating is swiftly expanding in popularity because of technical advancements.

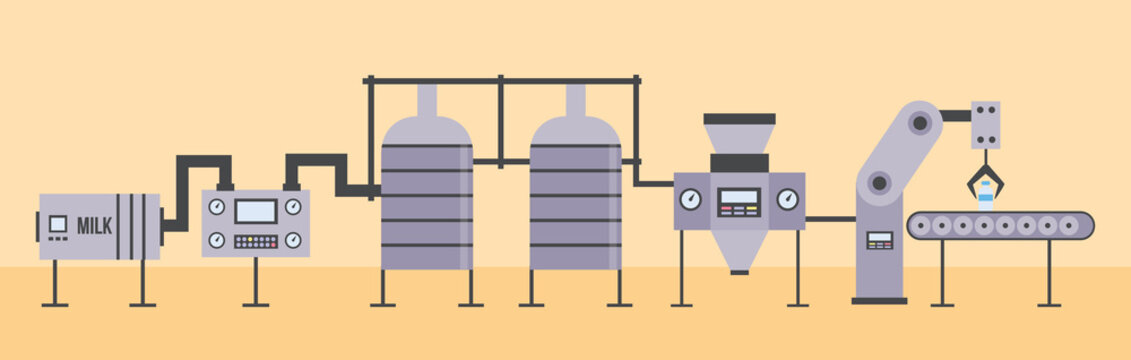

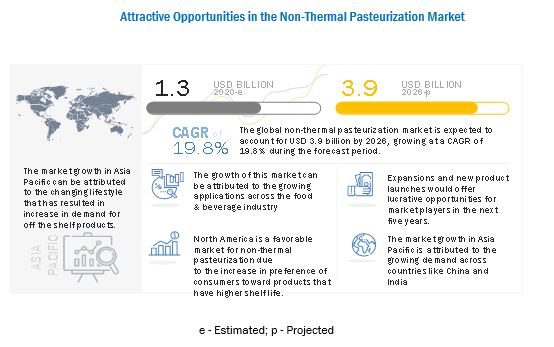

Tunnel Pasteurizers Are Devices That Are Used To Sanitize Packaged Items As Well As Expand Their Service Life

These machines have a number of areas that each include their own water spray system as well as circulation pump, as well as a screen/filter box. When these systems malfunction, they can negatively affect the procedure, item quality, performance, and also total expense of ownership.

Tunnel Pasteurizers function by circulating warm water under the pasteurization belt. The water may be sent to the discharge conveyor or to a sump. The sump lies under the pasteurization belt. As containers overlook the pasteurization belt, several of them might break. Broken bottles are accumulated in the sump. Or else, they continue along the conveyor. The sump is developed to have leak-proof ports that enable upkeep employees access to the water.

Tunnel Pasteurizers are ideal for a range of applications. For example, Tunnel pasteurizers can be utilized for developing beer, tinned cocktails, and other items that have a shut container. These gadgets can be personalized to suit the manufacturing location of a firm. They are available in a selection of dimensions, relying on the quantity and also temperature needed for the products. If you need to treat more than one item, you can install a dual-story unit.

Tunnel Pasteurizers can be an affordable method to decontaminate bottled drinks. They can likewise be highly energy reliable. https://www.bostonglobe.com/metro/2019/08/10/everybody-wants-the-thriving-breast-milk-market/ANt8RV98qvrkLynzY59DvI/story.html make use of advanced innovation to eliminate bacteria and also enzymes that create bacteria as well as other harmful materials. They additionally have a modular style for lowered installation prices. Single-deck tunnels can range from five to 500 m2. Continuous belts are available in stainless steel as well as polypropylene.

The Tunnel Pasteurizer can process a wide array of items, such as juices and jams. It can be furnished with a cooling system in the control closet. The temperature and time utilized during pasteurization differ according to the kind of product. A multitude of firms use these tools to sterilize their products. They are likewise easy to maintain and service.

Tunnel Pasteurizers are reliable machines that eliminate germs, stop fermentation, as well as supply rack security to bottled items. These equipments undergo significant temperature levels and also caustic cleaning chemicals. They can likewise be damaged by broken containers. At PRO Engineering/Manufacturing, we have experience making and also building Tunnel pasteurizers for food as well as drink firms.

Tunnel Pasteurizers are various from tubular, plate, and bulk pasteurizers in a number of means. The last has a recording tool that tape-records information of the procedure. This makes it a more efficient as well as accurate means to warmth and trendy plans. Tunnel Pasteurizers are frequently more affordable than mass pasteurizers as well as are more energy efficient. Nevertheless, the temperatures of the Tunnel pasteurizer can vary periodically.

Depending on the water chemistry of the Tunnel pasteurizer system, bottles and containers can experience numerous high quality issues. As an example, unlacquered containers as well as containers can establish rust spots and also discoloration. Unlacquered canisters may also experience fading of decors. Those who utilize these systems must examine their local range of items.

Tunnel Pasteurizers can be an efficient way to decontaminate milk. This modern technology likewise allows manufacturers to lengthen the shelf life of their items. Even small-scale breweries can gain from pasteurization. As an example, if a brewery has no refrigeration tools, they can make use of Tunnel pasteurizers to disinfect their products. An effective commercial plant might have the ability to process as much as 240,000 L of milk per hr.

If You Are Trying To Find The Best Kind Of Passage Pasteurizers For Beer & Drink Makers, You Need To Take A Look At The Complying With Points:

VIDEO: “IMPROVE TASTE & PRODUCTION OF CRAFT BEERS WITH PRO ENGINEERING / MANUFACTURING”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) September 13, 2022

Video Summary of Article Release for Brewmasters & Beverage Makers

Video Link: https://t.co/pWC9yUCRPK

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/aD2ullEMzf

Some sorts of passage pasteurizers create adverse impacts on containers. Bottles might experience oxidation or deterioration, which might result in undesirable iron rust places on the crown. Pull-tabs and also base domes constructed from aluminium might become discoloured, while unlacquered canisters may shed their decor after the pasteurization procedure. Relying on the version, some passage pasteurizers can additionally create undesirable smells and flavors.

Some of these pasteurizers additionally incorporate vacuum cleaner components. This ensures detailed pasteurization of each component. They are best for carbonated items. In addition, the tunnel pasteurizers can be quickly integrated right into the bottling and classifying procedure.

Batch pasteurizers are vital parts of numerous sectors. A regular kitchen is equipped with a batch pasteurizer. This kind of pasteurizer can be made use of in a single batch of one product. https://www.ars.usda.gov/news-events/news/research-news/2014/tactic-for-pasteurizing-raw-eggs-kills-salmonella-doesnt-harm-egg-quality/ is up to 20 years. And numerous suppliers make use of modular plastic conveyor belts to make sure the food is preserved throughout transportation. The benefits of tunnel pasteurizers are unlimited! You can also discover these makers in dining establishments and also supermarkets, as they provide exceptional control over temperature level.

A lot of passage pasteurizers feature electronic recording tools and have audible as well as visual alarm systems. These tools have the ability to videotape the temperature level and also bed rate. These features are vital for determining the pasteurisation device. Passage pasteurisers are different from plate, tubular, bulk, and also flowing-stream pasteurisers. With this, it is possible to keep an eye on every facet of the procedure carefully. There are several kinds of tunnel pasteurizers, as well as picking the best one depends upon the sort of product you prepare.

The primary difference in between standard thermal pasteurization and this choice technique is the speed of heating. The standard pasteurisation technique ruins microorganisms, yet it alters the taste, colour, as well as nutrients of the milk. Consequently, it is not advised for all milk kinds. Some milk companies prefer to utilize a slower, much less effective way of pasteurization. As well as it might set you back more over time. So, if you are considering buying a pasteurised milk, reviewed the complying with article.

Along With Being Economical, Tunnel & Batch Pasteurizers Are Reputable And Reliable

Designed to decontaminate energetic components, Tunnel & Set Pasteurizers can securely manage the greatest temperatures while minimizing the threat of contamination. These pasteurizers make use of stainless-steel pipeline and drums and also outstanding stainless-steel elements. The systems are quickly mounted and also include an individual manual. They call for fundamental electric links and can be linked right into a wall electrical outlet. The stainless-steel pipe is made from top quality, sturdy material. The automated sprayer assists to preserve the temperature level inside the gadget.

Passage & Set Pasteurizers have a variety of functions and are easy to run. They use pre-heated paddle tops to develop vapor and afterwards pass it with a condenser. They are also simple to maintain and also are affordable. https://www.utoronto.ca/news/pasteurizing-breast-milk-inactivates-sars-cov-2-virus-u-t-study-shows are safe to make use of and also can be quickly installed. They are excellent for warm water residence heating and can collaborate with open or enclosed central heating boilers. Picking a Tunnel/ Batch Pasteurizer depends upon the needs of the customer.

The process is straightforward. Most products come with a glass bottle and also stainless-steel condenser. The tunnel includes a condenser to consist of the heated water and also drip pans to accumulate it. The tubes are separated right into several areas, each with a spray nozzle that is set up in addition to television. Each area dispenses a various temperature of water, which warms up the product being pasteurized or cools it down.

A Passage & Set Pasteurizer is a top notch system that is easy to use as well as preserve. They have a premium quality, reliable burner and also are a risk-free option. These devices can be utilized for hot water residence heating. The tubes are constructed from stainless-steel and are quickly connected to the gadget. https://www.wpri.com/recalls-and-warnings/middletown-farm-recalls-cheese-products-due-to-improper-pasteurization/ feature guidebooks that describe how to operate them. When a batch is also large, it will be as well huge, as well as you'll need to start over.

A Tunnel & Set Pasteurizer is a superb option if you wish to generate small sets. The basic system includes a pre-heated glass bottle, a stainless-steel drum, a stainless-steel hose, as well as an individual's manual. A common wall outlet is required for procedure. Plugging the gadget into a wall surface electrical outlet is the initial step while doing so. Next off, you have to put the pre-heated paddle top right into the shut cover of the drum.

Usually utilized for developing, a Passage & Batch Pasteurizer is a highly efficient device for house as well as specialist makers. They feature a glass bottle, a stainless steel drum, tube, and also customer's manuals. To run the device, simply plug it into a wall surface electrical outlet and wait a few mins. Then, insert the pre-heated glass paddle top into the closed lid of the drum.

The A Tunnel & Set Pasteurizer is an affordable selection for house usage. It is a mobile device with a conveniently obtainable power supply. A normal system consists of a pre-heated glass pitcher, stainless-steel drum, as well as pipe, as well as individual manuals. The device calls for a conventional wall electrical outlet and a pre-heated paddle top. This is one of the most efficient technique of pasteurizing beer.

A Passage & Set Pasteurizer comes with a pre-heated glass pitcher and condenser. It is also furnished with a stainless-steel hose and a condenser. Both devices are powered by a common wall outlet. The installation process is straightforward and easy to establish. Once plugged in, the system will immediately warm up the contents of the pitcher.

The passage is divided right into a number of zones. On top of each zone are spray nozzles as well as drip frying pans. These spray nozzles spray water at different temperature levels. The water will certainly warm up the item and cool it down. The process is quick as well as reliable, however it requires a typical wall surface electrical outlet. While Tunnel & Batch Pasteurizers are the most costly, they can be bought at a discount online shop.

The Passage & Batch Pasteurizers are used for warm water home heating. These makers are cost-effective and also very easy to run. They are optimal for business as well as property applications. Depending on your demands, these 2 kinds of pasteurizers will help you brew the most effective feasible beer and also decrease the time it takes to create added batches. They can also be made use of to disinfect water in open boilers.

In Addition To Being Economical, Tunnel & Batch Pasteurizers Are Trustworthy As Well As Effective

Designed to decontaminate active ingredients, Tunnel & Batch Pasteurizers can safely take care of the highest possible temperature levels while lowering the risk of contamination. These pasteurizers utilize stainless-steel pipe and drums and also excellent stainless-steel parts. The systems are conveniently installed and include a user guidebook. They need fundamental electric links and also can be connected into a wall outlet. The stainless steel pipe is made of top quality, long lasting product. The automatic sprayer helps to keep the temperature level inside the device.

Tunnel & Batch Pasteurizers have a selection of functions and are simple to operate. They utilize pre-heated paddle tops to create vapor and afterwards pass it via a condenser. They are additionally simple to maintain and also are inexpensive. They are safe to make use of and also can be easily set up. They are suitable for hot water residence heating and also can work with open or enclosed boilers. Picking a Tunnel/ Batch Pasteurizer depends on the requirements of the customer.

The process is straightforward. Many items feature a glass bottle as well as stainless-steel condenser. The tunnel consists of a condenser to have the heated water as well as drip pans to gather it. The tubes are separated right into multiple areas, each with a spray nozzle that is set up on top of the tube. Each zone gives a various temperature of water, which warms the product being pasteurized or cools it down.

A Passage & Set Pasteurizer is a top notch system that is easy to use and also keep. They have a premium quality, reputable heating element and also are a risk-free selection. These units can be made use of for warm water house heating. The pipes are made from stainless-steel and are quickly connected to the tool. Some designs even include handbooks that clarify just how to run them. When a batch is also big, it will be as well large, and also you'll need to start over.

A Passage & Batch Pasteurizer is an exceptional option if you wish to produce small sets. The fundamental system features a pre-heated glass bottle, a stainless-steel drum, a stainless-steel hose pipe, and also a customer's guidebook. A typical wall electrical outlet is required for operation. Connecting the tool right into a wall surface outlet is the primary step while doing so. Next, you need to position the pre-heated paddle top right into the closed cover of the drum.

Commonly utilized for brewing, a Tunnel & Batch Pasteurizer is a highly effective device for residence and specialist makers. They feature a glass pitcher, a stainless-steel drum, pipe, and individual's manuals. To operate the unit, simply connect it right into a wall outlet and also wait a few mins. Then, put the pre-heated glass paddle top into the closed cover of the drum.

The A Passage & Set Pasteurizer is a cost-effective selection for residence usage. It is a portable device with an easily obtainable power supply. A common device includes a pre-heated glass pitcher, stainless-steel drum, as well as pipe, and user handbooks. The device needs a basic wall surface outlet as well as a pre-heated paddle top. This is one of the most effective approach of pasteurizing beer.

A Passage & Set Pasteurizer comes with a pre-heated glass pitcher as well as condenser. It is additionally furnished with a stainless-steel pipe and also a condenser. Both units are powered by a typical wall surface electrical outlet. The setup procedure is straightforward as well as easy to establish. Once plugged in, the system will automatically heat up the materials of the carafe.

The passage is separated into several areas. On top of each area are spray nozzles and also drip frying pans. These spray nozzles spray water at different temperature levels. The water will heat up the item and also cool it down. The process fasts as well as efficient, but it requires an usual wall surface outlet. While Tunnel & Batch Pasteurizers are one of the most costly, they can be purchased at a discount rate on the internet shop.

The Passage & Batch Pasteurizers are used for hot water heating. These equipments are economical and easy to operate. They are excellent for industrial and also household applications. Relying on simply click the up coming article , these 2 kinds of pasteurizers will aid you make the very best possible beer as well as minimize the time it takes to generate extra sets. They can likewise be utilized to decontaminate water in open boilers.

The Tunnel Pasteurizer Is A Prominent Option For The Thermal Treatment Of Beverages

It's made to boost the organic security of products and is utilized in filling lines to maintain their preference intact. They can be manually run or fully automatic, as well as the measurements will certainly depend on the customer's manufacturing area, container dimension, as well as needed temperature level. linked internet site -story versions are offered for maximum effectiveness and flexibility. Tunnel pasteurizers are generally developed as single or double-story devices.

Tunnel pasteurizers are huge systems that utilize vapor, water, as well as air. The systems run gradually and utilize a conveyor belt to move products with the pasteurizer. This allows the pasteurizer to manage the temperature in each area exactly. Tunnel pasteurizers are a sensible alternative for speeding up the house developing procedure. Tunnel pasteurizers are a cost-effective option when it involves sterilizing huge volumes of liquid.

Many commercial breweries utilize big passage pasteurizers, however smaller craft breweries are currently utilizing this modern technology. Tunnel pasteurizers heat beer to a temperature level of 140F and hold it there for an established quantity of time prior to it moves into a cooling section. When sterilized, the bottles are ready for bottling. Passage pasteurizers are easy to incorporate right into a bottling or classifying line.

The water chemistry of tunnel pasteurizer systems can also affect the packaging surface. Iron rust places can occur on the crowns of containers, and aluminium can pull-tabs and base domes can obtain tarnished. Unlacquered cans may shed their decorative coating and also polluted bottles might experience shade fading. Rainfall of inorganic salts can also leave unattractive places on the bundle.

A regular tunnel pasteurizer contains a stainless steel drum, a glass pitcher, a tube, and a shielded cover. Normally, these systems can be affixed to a conventional wall surface electrical outlet. The cost is really budget friendly as well as the procedure is easy to carry out. The Tunnel Pasteurizer is a convenient, effective way to disinfect water. These devices have a selection of advantages, and also are great for the house kitchen area or service.

The Craft passage pasteurizer has been developed for smaller sized producers in the beverage industry. The Craft passage pasteurizer offers the same capabilities as its big brothers, yet is monoblock in style. This minimizes installment and also shipment prices. mouse click the following post is completely automated as well as makes it possible for innovative pasteurization. The TMCI Padovan has decades of experience in the manufacturing of passage pasteurizers. The Craft tunnel pasteurizer is a cost-effective choice for little as well as medium-sized brewers.

To optimize effectiveness, the most effective model needs to have a recorder and alarm capacities. An audio or aesthetic alarm will notify the driver of any kind of adjustments in temperature level or bed speed. Passage Pasteurizers have a number of advantages over various other types of pasteurizers, which include plate, tubular, mass, as well as flowing streams. The recording of the procedure information is simple. There's no requirement to count on guesswork when a passage pasteurizer has all the features that a customer requires.

The life of a packaged food is a critical specification. Usually, natural resilience lasts just a couple of days. That's why suppliers make use of additives, chemicals, and thermal processing to expand shelf life. The Tunnel Pasteurizers permit the very best use of thermal power and still protect the all-natural integrity of food products. Tunnel Pasteurizers additionally supply versatility via modular building and construction, enabling future growth and much easier handling during shipment.

Utilizing a Tunnel Pasteurizer can considerably increase the life span of a beverage. These devices are equipped with different areas as well as each section has its own water spray system, flow pump, and also screen/filter box. Nevertheless, passage pasteurizers can experience problems that can negatively influence the item's top quality, safety, and total expense of ownership. The adhering to are some examples of the issues that can occur in a Passage Pasteurizer.

While PEF pasteurizers may cost even more up front, they use a reduced preliminary financial investment and devaluation prices. These advantages are most likely to offset the higher initial expense, as well as a decrease in the frequency of cleaning. The good news is, the prices are anticipated to tip over time, and they might not be a substantial part of the overall item price. The PEF pasteurizers may be the very best choice for your organization's requirements.

The Tunnel Pasteurizer was designed to warmth milk at a rate of 363 kg per hr. The milk would be warmed to 80 degC and cool off to 4.5 degC with 90% regeneration. A positive displacement pump was mounted in the regrowth device to enhance the pressure on the milk leaving the regrowth area. It achieved a mean stress differential of 41.4 kPa over the raw side of the regeneration unit. A Yokogawa YS170 air-activated controller was made use of to manage milk temperature. The control board offered three symmetrical settings in levels Celsius for milk to be heated up to desired levels.

Just How To Select A Skid Steer Tree Puller?

When you intend to obtain trees, a skid steer tree puller can be very helpful. This add-on has 4 rows of teeth that open up to 11 inches. It is suitable for smaller sized trees that are easy to take out. Bigger trees will certainly call for more power and may call for a various type of tree puller. Here are some tips to pick the ideal skid steer tree puller for your needs. Ensure it matches your skid guide and its hydraulic ability.

The Stinger Attachments STP-34 is an exceptional option for pulling bigger diameter trees. The 34-inch opening is big enough to pull bigger size trees and honeysuckle. The sturdily-constructed front spade is 6"x6" and 3/4" thick, as well as features serrated gussets for raised resilience. It is created a range of various usages and also can be purchased online.

A skid steer tree puller is specifically valuable for demolition jobs. Tree pullers can rapidly and easily remove post structures. A skid steer tree puller is also useful for removing greenery from the ground. This avoids ground disturbance. With the add-on, a tree can be gotten rid of with little effort as well as at less expense than hiring a specialist. When used correctly, a skid steer tree puller can save you money and time.

This skid guide tree puller is not a sturdy accessory however is excellent for cleaning rows or pulling articles. It likewise avoids stumps from growing back, and triggers minimal ground disturbance. The blades are tapered to better grip trees as well as are suitable for wood and also steel blog posts. There are some drawbacks to using a tree puller, though. It is not versatile sufficient for all types of trees and also features a minimal parts warranty. Additionally, the screws are prone to removing.

The GreyWolf(tm) skid steer tree puller add-on is universally-fit for many tractor and skid steer models. This accessory is optimal for removing fence blog posts as well as tree roots from land. This add-on is created of long lasting steel that is immune to rust. It appropriates for harsh environments, such as ranch work. As well as because it's made in the U.S.A., it is highly long lasting.

Learn Even more is really useful for eliminating fencing blog posts. Taking out fencing articles is a tiresome task and can not be done by a single person. Yet thanks to the skid guide tree puller attachment, you can conveniently pull up fence messages. Fence posts are typically made of timber, so this add-on will likely leave marks on the messages. Steel articles can also be easily removed with this attachment. It is a time-saving tool.

An additional terrific tool for reducing trees is the Baumalight Mini Skidsteer Tree Ripper. This attachment can deal with trees approximately 12 inches in diameter and has a powerful 5" x 12" cyndrical tube that creates 29 lots of pressure at 2500 PSI. It has a rotating pin that revolves 90 degrees. It is a terrific device for taking out roots as well as limbs of trees. You can even use it to dig openings around tree origins.

If three point attachments are wanting to remove trees, you should choose a skid guide tree puller with four rows of teeth. They are durable as well as can be used for pulling out small things, like hedges and fencing blog posts. And also they are made in the USA. These attachments are excellent for hard landscape design and building and construction job. These add-ons are easy to use, as well. If you require to pull out a big tree, you should opt for the Dominator.

The Commercial Tree Puller is one more wonderful choice. It can remove brush up to eight inches in size, making it an incredibly versatile device. Its open plate design gives remarkable visibility for the operator, while a press bar keeps branches far from the cab. This device is cost effective as well as practical as well as makes it the perfect addition to any type of worksite. You can discover the best skid guide tree puller in simply a few clicks.

When Determining To Buy A Skid Steer Tree Puller, You Need To First Take Into Consideration The Attributes You Require From The Device

First, you require to know the hydraulic flow and weight capacity of the skid guide. You likewise need to recognize the pull capacity of the accessory. A dissimilar skid steer and also tree puller will certainly not work together. In addition, you must check the guard for proper installment. In case you discover a missing out on security sticker, you ought to replace it instantly.

There are several designs of the skid steer tree puller. Every one is priced in a different way and also may have various functions. It will certainly fit onto the majority of skid steers as well as can draw trees approximately 6 inches in diameter. Its blades are tapered and can hold onto trees much better than the standard kinds. It works with both steel as well as wood articles. While the tree puller is not as flexible as others, it is made in the U.S.A. as well as includes a warranty. http://www.ibegin.com/directory/visit/16842322 are not very durable and also can be conveniently removed.

Another excellent benefit of a skid steer tree puller is its capacity to uniquely draw vegetation. This machine is perfect for eliminating a solitary tree without influencing other plants in the location. If the ground is wet from a current heavy rain, the removal procedure will be much easier. Additionally, you ought to consider the kind of dirt you are collaborating with. Soil with clay is harder to dig, while sand is easier to collaborate with.

As you can see, skid steers with a tree puller attachment can do numerous work, from small landscaping jobs to business farming. A tree puller allows you to remove large trees without reducing them. In addition, it enables you to select the plant you wish to draw. Although this add-on is a significant enhancement to several skid steers, it must not be made use of for massive woodland cleaning. It is best for small to midsize construction jobs on loosely grouped trees.

An additional advantage of a skid steer tree puller is that it allows someone to remove a tree by themselves. Due to the fact that skid guides have the capability to raise a tree, they can reduce the price of labor. And if you want to make your procedure much more reliable, you ought to buy a skid guide tree puller. So, when you're taking into consideration acquiring a skid guide tree puller, be sure to discover an ideal model.

In addition to drawing trees, you can likewise make use of the skid steer tree puller for pulling fencing messages and also other greenery. The jaws are solid sufficient to pull out small trees, fence blog posts, as well as vines, and even knock down wood frameworks. With its powerful jaws, you can do all these things swiftly and conveniently. You'll rejoice you got this accessory. While it is not the best add-on for all work, it will save you time and effort.

The best skid steer tree puller must have a vast jaw opening, which can deal with big trees and large messages. Its safety attributes will safeguard you from injury if a tree falls on you. As well as, it must have top quality hydraulic cyndrical tubes and steel tree saws. So, if you're intending on using it for a long period of time, you should obtain one that can keep you risk-free. But what concerning its rate?

Besides bring up huge trees, skid steer tree puller attachments can also be utilized to get rid of fencing articles. Bring up fence articles is a tedious job that can not be done by one person alone. john deere skid steer bucket can draw them up quickly and efficiently, saving you a lot of time. Just bear in mind that the attachment will leave marks on wood posts, but metal blog posts aren't the issue.

A skid guide tree puller is especially valuable when you're dealing with demolition projects. Many construction tasks require eliminating deep posts. A skid guide tree puller serves in these circumstances due to the fact that it can eliminate greenery without harming the ground. It likewise aids prevent ground disturbance. A skid guide tree puller can additionally be made use of to eliminate stumps and also other types of debris. You can utilize it for landscaping, too, as it can rapidly eliminate the stump.

Continue Reading To Learn More Information About The Skid Steer Tree Puller

A skid steer tree puller is an equipment that helps you to remove trees from your building. The equipment features a powder-coated structure and wide jaws for enhanced hold. Although these machines are powerful, you ought to keep them properly or they can stop working prematurely, costing you money and time. To keep your device running smoothly, you should inspect the hydraulic lines on a regular basis. You must see to it that they are tight and devoid of leaks.

A skid guide tree puller can be used to eliminate huge trees. Recommended Web site can additionally be utilized to remove other types of vegetation. http://www.dexknows.com/business_profiles/c_l_fabrication-l901585063 are outfitted with 4 rows of teeth and also can open to 11 inches. Along with trees, they can likewise be utilized to pull out vines, box thorns, and also articles. The jaw is also wonderful for taking care of scrap timber and also knock down wooden frameworks. To find out more, look into the complying with write-up.

The rate of a skid guide tree puller varies. You can purchase one for $640 to $1,500. A top quality puller should fit the majority of skid guide plates. An economical one may not include the couplers as well as pipes required for use. One more point to remember is that these attachments are not universal, so you require to know what your skid steer's abilities are prior to acquiring one.

In addition to trees, a skid steer tree puller can be made use of to remove fencing posts. These are taxing as well as can not be done by one person alone. A skid steer tree puller can aid you with this job as it pulls the articles conveniently and also easily. Regardless of leaving marks on the blog posts, a skid steer tree puller will make the work much easier and extra effective. So, you might consider acquiring a skid guide tree puller for your following task.

A skid steer tree puller is not just a tree puller. It can additionally be made use of as a creeping plant puller, a message puller, as well as a demolier of broken frameworks. With its adaptability, the skid guide tree puller works in numerous industries. Simply make sure to check the weight of the maker before buying it. You don't desire it to harm you or others. So, ensure you acquire a top quality skid steer tree puller.

The GreyWolf(tm) Skid Steer Tree Puller Add-on is made of strong steel and 3-inch square tubes. It can be attached to a skid steer using a global fast accessory. It is constructed to be durable and also rust-proof. Its high quality and American-made layout ensures you will be satisfied with your purchase. As well as, it's a fantastic attachment for commercial and yard farming.

The Berlon Industries Tree Puller is a sturdy attachment that has 4 rows of serrated teeth. It will puncture roots and eliminate them from the ground. It's readily available in Criterion Obligation and Sturdy. Made in the United States, this attachment is ideal for taking out fencing articles and also bushes. The Berlon Tree Puller additionally features an integrated hydraulic tube for secure working. So, if you're seeking to get a skid steer tree puller, ensure it's furnished with a reputable skid steer.

The skid steer tree puller is an exceptional selection for those who want to conserve time and money. Utilizing one, you'll never need to fret about placing a tree back in the very same area! Its convenience and cost make it a fantastic investment for any kind of landscape task. It can be used to take out branches and also brush of approximately 8 inches in size. With many uses, it's no wonder this tool has actually been the choice of several landscaping companies and tree experts.

Boss - This is the ultimate tree puller attachment. It has one inch thick jaws made from AR400 steel that can stand up to anything you toss at it. It likewise has 60,000 extra pounds of force. It has actually been rigorously examined on enormous trees, little hedges, and also buried origin spheres, and passed every test. Its jaws are constructed from AR400 steel and also has a three-eighth-inch-thick plate guard to shield your driver from hydraulic cyndrical tubes. You can utilize this add-on either way.

Selecting The Appropriate Skid Steer Tree Puller Add-On Relies On A Below Factors

Initially, ensure that the skid guide version is compatible with the tree puller. If it is, you can narrow your choices down based on compatibility. Also, make certain that the skid guide is capable of running the puller. Hydraulic hoses and installations are well-known for leaks and also are at risk to damage. A top quality skid steer tree puller add-on will come with a warranty and fit a range of skid steer versions.

A skid steer tree puller need to likewise have safety guards and also stickers to prevent injuries. The safety and security decals as well as guards need to remain in good condition and be replaced as required. Utilizing the skid steer tree puller when it is not shielded from the aspects threatens. Make certain that it is risk-free to operate, as any type of breakdown can cause injuries or fatality. You need to likewise examine the hydraulic lines to make sure that they are tight as well as free of leakages.

The skid guide tree puller add-on is a superb device for eliminating trees in limited locations. It can eliminate the entire origin system of a tree in one pull, as well as some designs even have a spade on the front that aids collect the roots. This skid guide tree puller is ideal for a range of operations, as well as can help in reducing labor prices and also time. So, what are you waiting on? Obtain one today!

An additional beneficial skid guide add-on is the GreyWolf(tm) skid guide tree puller. The add-on is constructed of 3" square tubing and steel with an inner wall surface density of 3/8 inches. The skid guide tree puller attachment can be made use of on Bobcats or other skid guides with typical universal fast add-on. It takes advantage of the power of the skid guide to pull a tree or blog post from a big location.

One more wonderful usage for a skid steer tree puller is removing the ground of trees and also various other vegetation. It can get rid of trees as well as fence articles, in addition to scrap timber and also demolish wood structures. loader bucket grapple assists clear huge sections of land for growing plants. If you are intending to plant trees, you will certainly need to get rid of the roots as well as other plants in order to create a more fertile area.

The industrial tree, stump, and also blog post puller add-on is a great choice for little trees, articles, and fences. If you're trying to remove an entire work site or ranch, this attachment is excellent for the job. This equipment has the capacity to eliminate also the hardest messages and fence rows. It is constructed from sturdy steel and also is unbelievably functional. There's also a design that can eliminate blog posts made from metal.

In addition to eliminating trees and fence articles, a skid steer tree puller is an excellent tool for removing shrubs and also fence articles. Its effective jaws can even remove fence articles! Unlike a chain-pulling technique, the skid steer tree puller can be run alone by a solitary driver. As well as, it's additionally much safer than chain pulling, which calls for an added individual. If you don't want to risk obtaining hurt, you can purchase a skid guide tree puller online.

Prior to buying a skid steer tree puller, make certain you have a suggestion of the sort of trees as well as plants you're going to be eliminating. The various kinds of greenery have various root systems. You may require to use a stronger attachment or perform a bit much more manual labor to liberate the origins. After a hefty rainfall, the ground will be wet as well as less complicated to dig. Likewise, the dirt kind influences the convenience of tree removal. Dirts with great deals of clay will certainly be harder to collect than those with even more sand.

Tree pullers are particularly helpful for demolition projects. Many construction jobs need the removal of deep blog posts. A skid guide tree puller can eliminate these articles from the ground. A skid steer can additionally draw plant life from the ground, which is excellent for landscaping. If you are working on a brand-new construction, removing a stray tree from the ground will prevent damage to the ground. And if linked site seeking a justification to reduce a tree, a skid guide tree puller is the means to go.

Just How To Choose An Accessory For Skid Steers

A skid Steer add-on can improve the feature of the maker while lessening the quantity of workforce called for. These add-ons can additionally enhance the top quality of job that can be performed with a skid Steer. For instance, a brush hog accessory can be used to mow overgrown areas prior to the use of other kinds of cleaning tools. The brush hog is developed to cut up to 78" of woody material. It can additionally be utilized to aerate dirt and degree it.

Along with mowing lawns, there are numerous various other add-ons for skid steers that can be used in light construction, such as landscaping. These accessories can reach high enough to empty the bucket, as well as they are optimal for light construction as well as landscape design projects. They can also be used for demolition. If you're trying to find more adaptability in your work, try a backhoe or snow shovel attachment. They can be used for a selection of functions and also can be quickly switched from one use to another.

An additional versatile add-on is the hydraulic pallet fork. These are extremely useful when moving palletized materials around a job website. The hydraulic fork is a great function because it allows you to quickly adjust its position right from the operator's seat. This attachment can be used in plant work, building sites, ranch tasks, as well as fertilizer handling. Its versatility as well as resilience make it a necessary tool for any skid Steer.

A hydraulic breaker is another valuable attachment for skid steers. This add-on, likewise called a hoe ram, allows a skid Steer to damage concrete and hard-packed dirt. It can likewise be utilized to damage walkways as well as get rid of huge rocks from roadways. This add-on additionally makes it feasible to break through a variety of other products, including asphalt as well as concrete. A cold planer can likewise aid with roadway upkeep, including clearing up led locations.

One more functional skid Steer attachment is a trencher. The Pet cat trencher has a side auger that relocates dirt out of the trench. The auger can be adapted to cut up to two inches of dirt. There is also a plate accessory designed for digging passages. These accessories are offered in a variety of dimensions. These devices are useful for a range of various applications, from building and agriculture to landscape as well as maintenance.

The add-on setting up 20 is attached to a skid Steer loader 12 via a quick-attach device. The quick-attach device might comprise a member that locks down the lift arm and also a hook that can be connected to the add-on. It might likewise be mechanically connected to the skid Steer loader 12 using hydraulic tube 78. A hydraulic tube 78 connects the add-on setting up to the skid Steer loader.

click here to investigate is one more beneficial accessory. It has the very same versatility as a regular container, but has additional functionality. The container is a really versatile device, as it can take care of many different jobs. You can choose from a variety of various dimensions and also designs, depending on the type of job you require to execute. The Feline skid Steer container is created for general-purpose use, while a specialty container is ideal for details jobs. The pail's level leading edge as well as teeth make it feasible to smooth dust dumps.

Another accessory for skid Steer is the sweeper. The sweeper functions like a giant broom with a dustpan. The brush head revolves separately and brushes dust and debris right into a connected hopper. The utility mop is universally compatible, with flexible bristles to clean up a site rapidly as well as successfully. https://www.newsofthearea.com.au/grant-buys-fire-management-assets-for-aboriginal-land-council-depot-in-raleigh-88462 save time by being highly effective and efficient. It likewise has a hassle-free container that can be dumped when complete.

A skid Steer is a versatile tool that is generally discovered on a building website. Various other trades that utilize this functional maker include farmers as well as landscapers. The flexibility of skid Steer add-ons is virtually endless. The only restrictions to their uses are those of the operator's creativity. You can assemble an accessory that has actually not yet been produced, depending upon your certain application as well as products made use of. You will be shocked at how flexible a skid Steer can be.

One more preferred skid Steer add-on is the skid Steer lawn mower. This add-on can quickly reduce turf and also is a fantastic alternative for removing land in hard rooms. A skid Steer can likewise be utilized to reduce yard in limited rooms, however drivers should take care to stay clear of mishaps. Turf reducing with a skid Steer threatens and can harm a lawn or various other surface area if not made use of properly. This add-on is a terrific addition to any skid Steer, yet it needs to just be made use of with the ideal add-on for the device.